GALVANIZED CONVEYORS

(SINGLE-CHAIN)

To operate your conveying system at maximum efficiency, your material handling requirements must be properly matched with the optimum elevator width. We offer a complete selection of elevator widths... 9", 11" and 13"... to meet different material handling requirements.

9" WIDTH — will handle most sizes of silo unloaders

11" and 13" WIDTH — use where two, large silo unloaders are discharging into elevator at once.

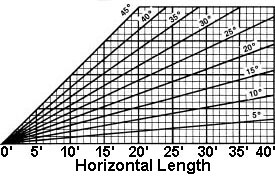

9", 11" or 13" elevators will handle well. Do not positionelevator at an angle greater than 45°

A 9", 11" or 13" elevator can be used

A 9", 11" or 13" elevator can be used.

We recommend an 11" or 13" elevator. Do not overload, especially for soybean meal

We recommend a 9", 11" or 13" elevator

Use a 9", 11" or 13" elevator

We recommend a 9", 11" or 13" elevator

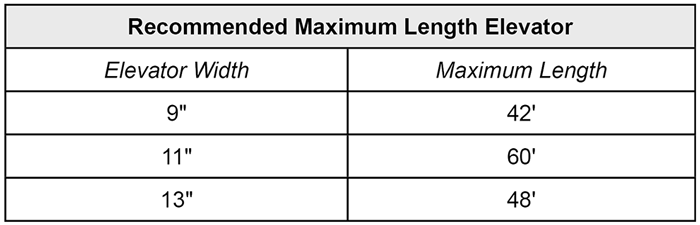

Selecting the Right Length Elevator

Click the image below to enlarge

Click here to download this chart

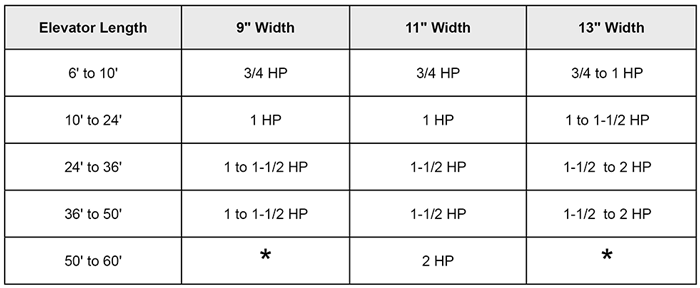

Selecting the Right Size Motor

Click the image below to enlarge

Click here to download this chart

* Refer to “Recommended Maximum Length” table above

WARNING: Electric motor must be totally enclosed, fan cooled and have a manual reset overload protector. Motor starting, stopping and motor reset controls must be located so that the operator has view of the entire operation. Covers (See Accessories) are required on all lower sections of elevator located within 7’ of floor or working level or within reach of people. Failure to heed could result in personal injury or death.