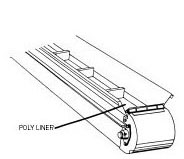

POLY LINER

Conveyors

- Super-slick, self-lubricating liner prevents freezedown

- Prevents moisture from penetrating surface — reduces chain stretching — increases chain life.

- Lowers energy consumption by up to 30%

- Makes old conveyors better than new — extends life of new conveyors

Caution: Existing conveyor must be structurally sound to provide adequate underlying support for liner

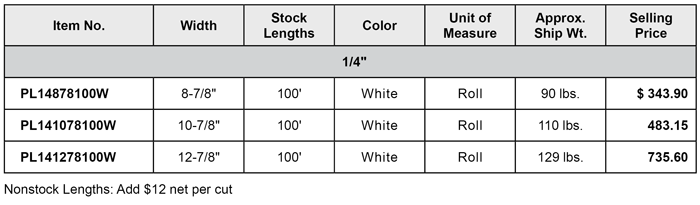

CONVEYOR LINER

Note: Read "Selecting the Right Thickness... Width... Length"

Nonstock Lengths: Add $17 net per cut

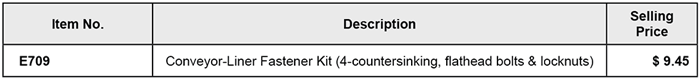

CONVEYOR-LINER FASTENER KIT

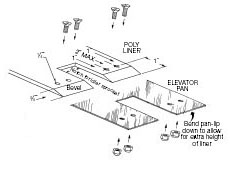

INSTALLATION INSTRUCTIONS

- Read General Installation Tips

- Cut pan liner to length of pan, less 1/16" per foot (up to 2" max), to allow for expansion.

- Notch liner for idler and drive sprockets.

- Drill liner and pan on intake end only, per above drawing.

- Fasten liner to pan (at intake end only), using 4-countersinking, flathead bolts and locknuts. See Conveyor-Liner Fastener Kit"

- Bevel front-edge of liner back 3/4", using a hand grinder or file, so flights don't catch on liner.

- Bend (hammer) down intake end of pan as required, to allow flight clearance for additional height of liner.

Important: Check entire length of elevator for adequate side clearance between liner and both sidewalls (1/16" on each side up to 13" wide, 1/8" on each side if over 13" wide). Grind or block-plane if needed, so liner can expand lengthwise without binding and humping.