GALVANIZED CONVEYORS

(SINGLE-CHAIN)

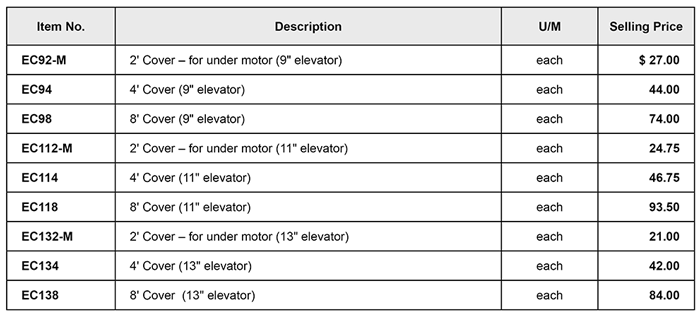

- Ideal for shielding materials from rain and snow

- Prevents wind from blowing light material out of trough

- Covers snap on easily — can be quickly removed for operator inspection

Note: When ordering — reduce length by 2' to allow for hopper. Covers available in the following lengths only:

Click the image below to enlarge

Click here to download this chart

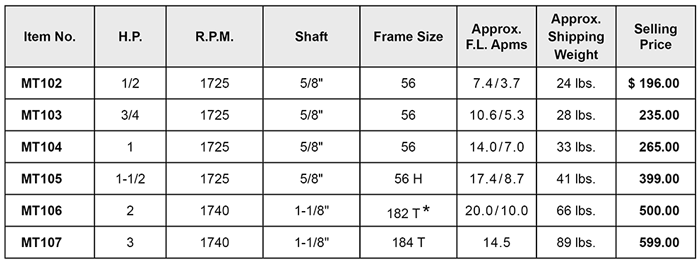

- Heavy-duty, Farm Rated, capacitor-start motors are totally enclosed and fan cooled (single-phase)

- Manual reset for thermal protection

- Prelubricated, double-shielded ball bearings

- Both windings and grease effective at temperatures down to minus 40° F

- Motors supplied with slinger on shaft and gasketed conduit box

- Rotation easily reversed

- 1-year limited motor warranty

- Motor cord & switch not included (purchase from your electrician).

Click the image below to enlarge

Click here to download this chart

NOTE: Above motors all 115/230 voltage

* Heavier 182 frame (rather than lighter 145 frame) recommended for our elevators — provides better starting performance/longer life.

WARNING: Electric motor must be totally enclosed, fan cooled and have a manual reset overload protector. Motor starting, stopping and motor reset controls must be located so that the operator has view of the entire operation. Wiring should be done by a certified electrician in accordance with local and national codes.

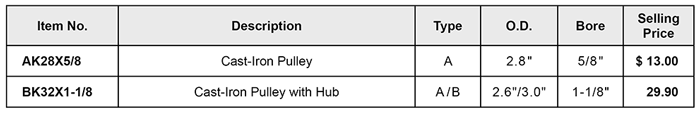

- Cast iron... single-groove motor pulleys

- Precision cast and machined for perfect balance

- Solid construction on fixed bore with hollow-head set screw and standard keyway

Click the image below to enlarge

Click here to download this chart

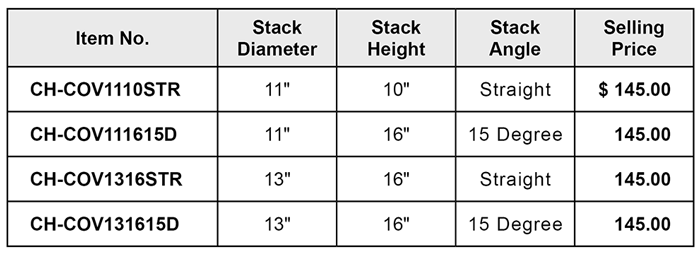

- Use when silage is fed directly from silo clean-chute tube — prevents silage spillover — reduces wind losses

NOTE: Requires straight hopper — order separately below

Note: Requires straight hopper — order separately below

Clean-Chute Cover w/Stack

Click the image below to enlarge

Click here to download this chart

NOTE: Any cover above will fit all straight hopper sizes.

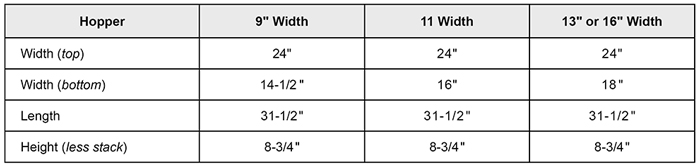

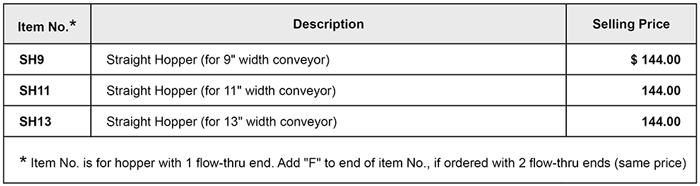

- Use when elevator is being fed from two locations... or when clean-chute cover above is ordered

- 4-sided hopper easily snaps on at any point along elevator

- Illustrated with 1 flow-thru end. Order with 2 flow-thru ends if hopper installed at location following 1st intake hopper.

Click the image below to enlarge

Click here to download this chart

Note: If straight hopper is desired, RATHER than sliding incline hopper furnished with elevator — please state on order. A price allowance will be granted for cost of sliding incline hopper.

Click the image below to enlarge

Click here to download this chart

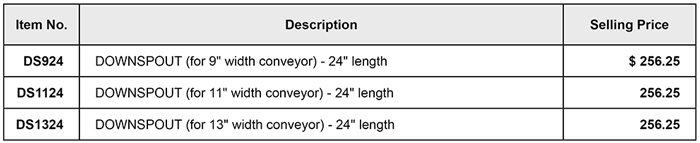

- 4-sided downspout controls discharge flow of material

- Directs material to where you want it

- Reduces wind losses

- Attaches directly to discharge end of elevator

Click the image below to enlarge

Click here to download this chart

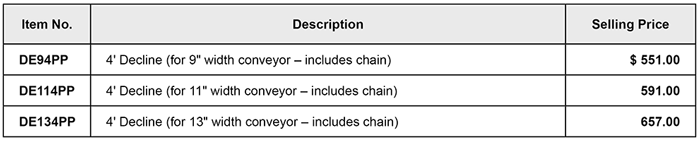

- Easily adjusts up to 40° angle

- Permits custom installations under or over obstacles

- 4' decline furnished with sturdier, angle-iron connecting joints

- Decline sections can be factory installed at any point along elevator

- Self-lubricating poly wear liner at hinge — for quieter, longer-life operation

Note: Declines furnished with chain and with poly liner for pan.

Click the image below to enlarge